Important Notes on Your New Electronic StraightGate

- Turbosmart

accepts no responsibility whatsoever for incorrect installation of this product

which is potentially hazardous and can cause serious engine damage or personal

injury.

- The

Straight external eWastegate is designed for use with a turbocharger that does

not have an internal wastegate.

- Consult your local specialist before

setting your desired boost pressure, setting boost beyond your engines

capability may result in engine damage.

- Use

only high-quality fittings ensuring maximum sealing reliability.

- It is important during the setup of the eWastegate, that some precautions are taken to ensure that the unit does not malfunction. Firstly, the output from the ECU should be limited to 15%. As well as an inline fuse (5A-10A) or breaker to protect the Straight Gate. Once correct operation has been verified the fuse and limits can be restored to a more suitable limit. When using third party controllers, a spare motor is recommended as it doesn't have the same safety features that are included in the Black Box Controller and has been common for customers to exceed the current limit and destroy the motor.

- Incorrectly wiring sensor to

Chassis ground will cause calibration issues, Sensor Ground must be connected

to the ECU Sensor ground. Do NOT connect ECU Grounds and Chassis Grounds

together they must remain separate.

- Correctly setting up a sensible

boost control strategy to ensure engine safety is highly recommended.

Recommendations

- Always disconnect motor wires before removing the end cap

off the actuator

- Allow for adequate cool airflow around electronic actuator

paired with water cooling.

- DO NOT Mount the electronic wastegate so that the electronic

actuator is less than 100mm from a heat source.

- DO NOT wrap the body of the wastegate with exhaust wrap.

- Fitting your Electronic

Straight Wastegate may require fabrication or modification to your exhaust

manifold. Turbosmart recommends that your wastegate is fitted by an

appropriately qualified technician.

- Turbosmart recommends that the engines Air/Fuel ratio is

checked while setting the desired boost pressure, as any increase in boost

pressure can cause the engine to run “LEAN”, resulting in possible engine

damage.

- Turbosmart recommends that boost

pressure is set using a dynamometer and not on public roads.

- Turbosmart recommends that a boost

gauge be permanently fitted to the vehicle.

Kit Contents

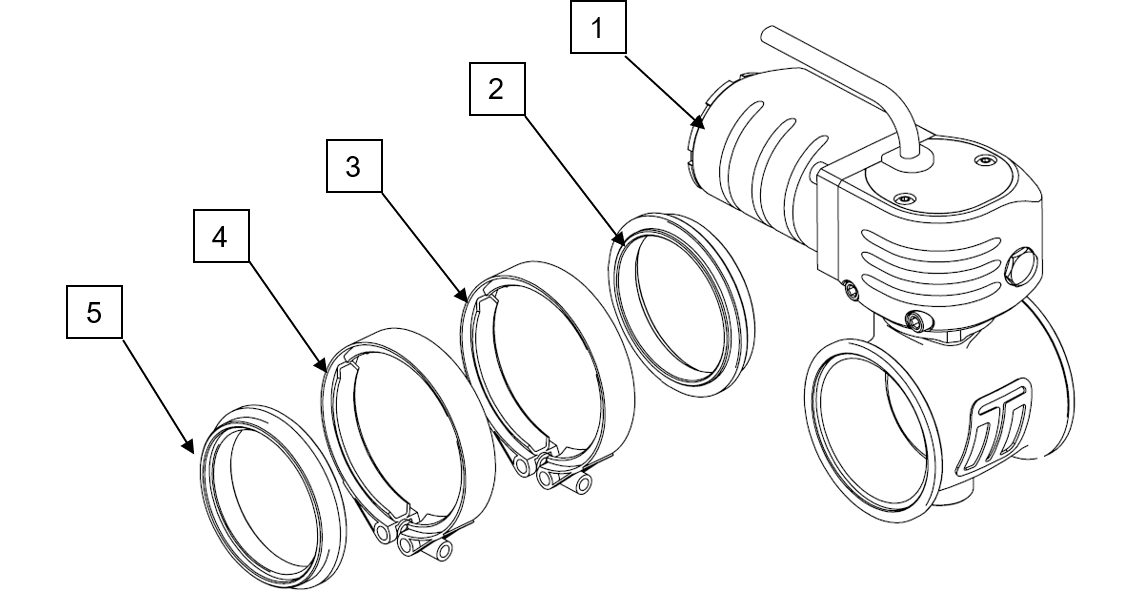

Part | Description | Use | QTY |

1 | Turbosmart

Electronic Waste Gate | Main unit | 1 |

2 | Inlet

V-Band clamp | Inlet V-band clamp | 1 |

3 | Inlet

Weld flange | Inlet V-band weld flange (O-Ring included) | 1 |

4 | Outlet

V-Band clamp | Outlet V-band clamp | 1 |

5 | Outlet

weld flange | Outlet V-band weld flange (O-ring included) | 1 |

6 | Turbosmart Sticker | Turbosmart sticker | 1 |

¼” drive socket 5mm

¼” drive extension

¼” drive ratchet

3/8” square drive deep socket

14mm square drive deep socket

Square drive ratchet wrench

Torque wrench (3/8” drive)

Metric Allen Key set - 2.5mm,3mm, 4mm

Allen key

Non-marking spanners to tighten

fittings

Suggested lubricants and Sealants

- Loctite 243 Thread locker

- Loctite 567 Thread Sealant

- Resbond 907TS Red

- Penetrating oil

- Inox MX8 spray grease (Or Equvilant)

CAUTION! It is important

during the setup of the eGate, that some precautions are taken to ensure that

the unit does not malfunction. Firstly, the output from the ECU should be

limited to 15%. As well as an inline fuse (5A-10A) or breaker to protect the

eGate. Once correct operation has been completed, initial safety setups can be

lifted to operational limits.

HOW TO

USE

The Turbosmart Straight Gate is a brand-new way

to control boost pressure, it involves using an electric motor to drive the

position of the butterfly valve, this allows far greater control over

conventional pneumatic boost control during its actuation on the car. This

paired with an aftermarket ECU controlling the straight gate, allows for plenty

of new and safer ways to control boost on your car.

The Body will need to be fitted to the vehicle. This involves the two V

Bands clamps, the Inlet (fitted on the exhaust manifold), and the outlet which

is where the regulated exhaust gases are bypassed. It is important to have the butterfly

valve manually set to about the middle of its stroke. This will allow for an

easier installation. The Straight Gate can be used in both directions.

Please see below for a more detailed and

helpful way of installing the Turbosmart Electronic

Straight Wastegate.

Turbosmart Electronic Straight Gate will require periodic reapplication of spray grease such as Inox MX8 spray (Any high temperature high pressure grease will suffice) grease. It is important that the manual override is used to move the butterfly valve through its range of motion, allowing the grease to be applied throughout the entire butterfly valve gearbox. Turbosmart recommends that this is done regularly at least half yearly or more in demanding temperature environments.

Inspecting motor operation is important to do when using a third party controller incase of issues with the motor. This isn't an issue with the Black Box Controller. Inspection should be done for motor operation after heavy use sessions such as racing weekends

It is also important to check V Band tightness after the wastegate has run through a couple of heat cycles. To ensure that the Straight Gate is seated and sealing correctly.

The Turbosmart Electronic Straight Wastegate

has a maximum thermal stress of 1250degC (2282degF) for 24hr if thermally cooled with the

water-cooling ports. It is important that the actuator internal housing doesn’t go above a temperature of 150degC (302degF)

as this may cause damage to the internal electronics. Turbosmart recommends

that the eWastegate is water cooled and paired with good airflow over the body

to help regulate temperature. Turbosmart also recommends data logging the

temperature sensor that is seen inside the actuator.

It is recommended that water cooling is in line

with the turbo this will increase the longevity of the Electronic Straight Gate

and allow it to operate seamlessly. This does depend on the certain application

and the rate and period at which the Electronic Straight Gate is exposed to the

high temperatures.

It is important that the basic tuning

parameters are discussed with a trained professional, please consult your ECU

manufacture. There are a few basic parameters that are worth noting.

Motor polarity is important, Due to the nature of

PID controllers (Proportional-integral-derivative controller) the Electronic

Straight Gate will be targeting a set position, this will move further away if

the motor polarity is wrong as it is trying to reach its setpoint.

Current limitations, it is important that

the Current that is driven through the motor is limited to no more than 20amps

for more than 1 second and 5 amps for more than 5 seconds. It is important that

the current values such as the dead band are correctly set in the ECU to allow

for the motor to only be active if needed.

Sensor Diagnostic limits should be monitored for

values that are lower than 0.1V and higher and 2.15V with respect to the

Temperature sensor and 0.1V-4.9V with the position sensor. It is also

recommended that safety tuning strategies are in place to lower temperatures if

the eWastegate internally reaches a temperature of 150degC (302degF).

Butterfly Position limits should be set to target

0% for butterfly closed and 90% for completely open, Since the design of the

end stops is biased to operate better with the butterfly in the closed position

it is recommended to avoid opening the butterfly at full opening.

Boost cut should be set to

ensure the safety of your engine a sensible boost cut should be set with in the

ECU to control any possible over boost issues that could be detrimentally to

your engine.

The new Turbosmart Electronic Straight Gate is

Turbosmart’s addition to its electronic wastegate line-up. A new level of

control is now available with the butterfly valve and offers the option for

customers who require another packaging or new level of control.

Control

With the introduction of the electronic

motor to drive the Electronic Straight Gate, a new level of control is now available to

boost control, there is a wide range of tuning strategies that can be

implemented to better control boost as well as engine protection. This

allows the Engine to maintain much better control over the turbocharger.

Adjustability

The straight gate now offers 3 options

for the motor and body to be mounted in, this is coupled with infinite

possibilities of the body and exhaust piping with the weld flanges. So, if you

need the Electronic Straight Gate mounted in the opposite orientation to stop

fouling with parts within the engine bay, there is an orientation that is

suitable for the Electronic Straight Gate to operate in. This mixed without the need of having to remove and

reassemble due to changes in base wastegate spring pressure the Electronic

Straight Gate has next level control

adjustability of the position of the wastegate butterfly valve.

Upgrades and Servicing

Due to the modular construction, the new range is also upgradeable

and completely serviceable, as all components can be removed or upgraded.

Components have been tested for over one million cycles, so reliability is

rock-solid.

The new straight wastegate is a world first in its class It

features excellent flow properties thanks to our world-leading engineering and

simulation abilities. Thermal performance is a critical key performance factor

within the design of all our products. Thermal stability and longevity are

further extended with the liquid cooling ports for further thermal performance

if required.

Mounting your new Turbosmart Electronic Straight

Wastegate

The weld flanges should be

welded to your exhaust system. The weld flanges are compatible with Stainless

Steel and Mild steel welding rod material.

The Straight Gate utilises

WG60 Outlet Flanges, this allows for a straight swap over for engines running

WG60 Valves. A new exhaust side will need to fabricated for cars running the

poppet valve.

For best results, an attempt

should be made, if space allows, to mount the Straight Gate at an angle to the

exhaust flow to allow for better flow than a 90-degree mounting. See the

schematic diagrams below for examples of mounting positions.

NOTE! The Straight Gate can

be used in both directions. Both directions will regulate the same. It is

advisable however to place the Butterfly Valve pins exhaust side up.

Water

cooling is highly recommended for sustained heat exposure.

(Best Flow) Symmetric mounting allows an excellent flow of

exhaust to the Straight Gate

(Good Flow) Angle mounting allows a good flow of exhaust

flow to the Straight Gate.

(Poor Flow) 90 Degree mounting gives poor exhaust flow to

the Straight Gate and in some circumstances may contribute to over boosting.

Not Recommended - Less than 90 Degree Mounting. An angle mounting as shown in not recommended

and gives extremely

poor exhaust flow to the Straight Gate which can contribute

to poor boost control and over boosting.

CAUTION! Do not place the Straight Gate

near a significant heat source as this could shorten the life of the internal

electronics.

CAUTION! Do not place the Straight Gate

near a significant heat source as this could shorten the life of the internal

electronics.

Fitting the StraightGate

Even though possible

to mount the Straight gate in both directions, it is suggested that the

Butterfly valve pins are facing towards the exhaust exit.

Prior to mounting the Straight Gate, place

v-band (Figure 10) over weld on flange by unscrewing the nut on the v-band as

far out as possible and then squeezing the bolt in a syringe motion to expand

the v-band (squeeze the dots together below). Once the v-band is in its fully

expanded position, slide the v-band over the flange to allow for the wastegate

to be installed.

Using the 3/8” deep socket and a torque wrench Tighten

the V-Band to 7N.m (5 ft/lbs). Ensure the wastegate is home correctly while

torquing the nut to not have a false torque as this will likely contribute to

exhaust leaks.

It is important that the butterfly valve sits

slightly open for installation. This allows for no interference during the

installation process. This can be adjusted via the manual override.

Connecting your Turbosmart Electronic Wastegate

The Turbosmart Electronic wastegate comes unterminated with 7 wires.

Wiring Pinout

Revision B (current) – Wiring

| Colour | Description |

1 single core wire each | Large Gauge Red | Motor A tending towards 0% |

Large Gauge Black | Motor B tending towards 100% |

Multi Core Wire | Red** | 5V |

Black*** | Sensor ground 0V |

White | Position Signal 0-5V |

Blue (Rev B Only) | *Unfiltered Signal Output (Position Output) |

Yellow (Orange Rev A) | Temperature Signal 0-5V

|

*Note: The Blue (unfiltered position signal) is not required for use & is for development purposes only.

**Note: The 5V red wire has no reverse polarity protection, use only 5V wired in correctly.

**Note: The sensor ground must be grounded at the ECU Sensor ground and NOT the chassis

Sensor Voltage Limits

| Deg C (Deg F) | Temperature Sensor Output (mV) |

| 0 (32) | 2630 |

| 150 (302) | 538 |

| Position Sensor | Target Voltage (V) | Duty Cycle |

| 100% (Open) | 0.2-0.6V | ~16% |

| 0% (Closed) | 4.2-4.6V | -84% |

CAUTION! Turbosmart recommends calibrating the position sensor before connecting the motor wires to your motor drive.

The two large wires are directly connected to the motor of the wastegate and need to be connected to high power drives in a Full bridge configuration like that of an electronic throttle drive circuit, see your ECU supplier documents for suitable connections. Turbosmart recommends the eWastegate should be driven by an External dual H-Bridge, which is at least 20A for seamless operation.

Connect the small Red Wire to a 5V power source from your ECU as well as the Black wire to Sensor ground. Connect the white wire to a 0-5V analogue input on your ecu as well as the orange temperature sensor signal. The blue wire (Revision B only) is an unfiltered position output signal for development purposes - This can be left unterminated.

CAUTION!

- Whilst the temperature sensor is not required for operation it is recommended for activating failsafe protocols.

- Ensure all connections are high quality and away from any heat source.

It is important during the setup of the eGate, that some precautions are taken to ensure that the unit does not malfunction. Firstly, the output from the ECU should be limited to 15%. As well as an inline fuse (5A-10A) or breaker to protect the eGate. Once correct operation has been verified the fuse and limits can be removed.

Calibration

CAUTION! Disconnect the motor wires to prevent

accidental spin up.

To calibrate the electronic straight gate

firstly the manual override cap must be removed to allow access to the manual

override. A non marking 14mm is required to remove the cap from the body.

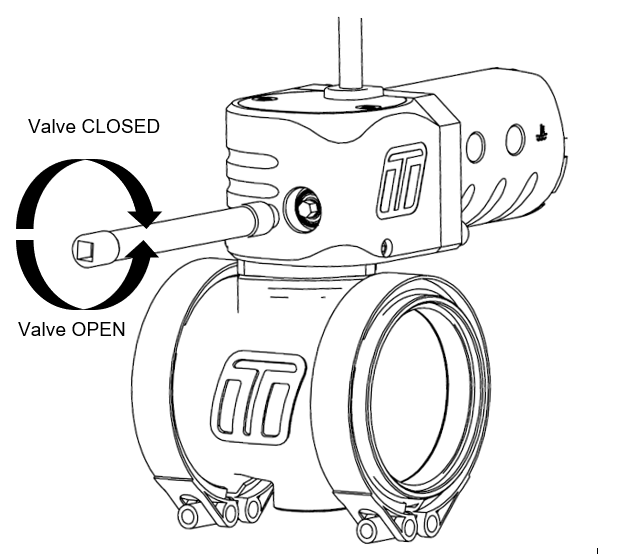

Using a ¼” drive extension with a 5mm socket, turn the manual override in a clockwise direction with your fingers until the mechanism stops rotating. In this position the butterfly valve should be home against the valve seat and will be your 0% position.

CAUTION! Do not apply

excessive force to the manual override, doing so will damage the product and

effect the performance.

Using

your ECU manager software, read the voltage from the sensor and set this as

your closed position.

Wind

the manual adjustment in an anticlockwise direction until it stops. From this

position rotate the adjustment 2 full turns in a clockwise direction. Allowing the gate to sit in the roughly 50% Valve position, as to ensure that the valve isn't sitting on it's hard stops.

Monitor

sensor signal voltage to ensure no wrap around occurs throughout the stroke of

the butterfly valve that could affect operation.

CAUTION! It

is critical not to set the 100% position at the end of the travel as this may

lead to seizing of the wastegate and overloading the system.

NOTE! Turbosmart

recommends allowing additional clearance from the end stops until the wastegate

control is tuned to minimise risk of overshoot into end stops at high speeds.

NOTE! Turbosmart

recommends allowing additional clearance from the end stops until the wastegate

control is tuned to minimise risk of overshoot into end stops at high speeds.

Tuning

The eWastegate will come calibrated from

Turbosmart, the targeted values have been set with regards to the position

sensor are approx. 0.5V (completely open) and approx. 4.5V as (completely

closed), It is important to note that as the wastegate butterfly valve moves

through its range of motion that the butterfly valves are monitored to move

from 4.5V decreasing to 0.5V, 0% open to 100% open. This should be done manually with the ECU

package monitoring Voltage Values. The electronic motor should be disconnected

at this point.

Voltage wraps around will cause errors with the

eWastegate, this is when the Voltage increases from 4.8V up to 5V and jumps

through to 0V.

| Position Sensor | Target Voltage (V) | Duty Cycle |

| 100% (Open) | 0.2-0.6V | ~16% |

| 0% (Closed) | 4.2-4.6V | -84% |

It

is important to set up the correct limits manually with eWastegate. Turbosmart

recommends that the butterfly valve is only ever driven electronically to the

maximum butterfly position of 90 %.

Driving

the butterfly valve to 100% will cause increased wear on components such as the

electronic motor as it tries to force the butterfly valve to completely open.

Adjust the calibration to allow plenty of

overshoot to the end stops of the butterfly valve, recalibrate as above once

you have good control of butterfly position.

PLEASE

NOTE: That temperatures over 180 degC (356degF) will create an error in the

temperature sensor readings. Therefore, the internal temperature is rated to a

temperature of 150degC (302degF) it is recommended to log and place sufficient

alarms to monitor this.

PLEASE NOTE: When driving the electronic actuator, the

current should be limit to no more than 20 amps at a period of 1 second

and 5 amps for more than 5 seconds.

Follow your ECU manufacturers guidelines for

tuning wastegate servo control. Ensure dead band is set to a reasonable level

to not have the output active when not needed.

Sensor Linearisation

Due to the nature of the

butterfly valve design, the flow characteristics are nonlinear. In some cases,

it may be advantages to correlate the linear sensor output to match the flow of

the valve. The following plot compares butterfly valve position with valve

flow. A 3rd order polynomial is provided to relate sensor position

to flow. Note due to the design of the electronic straight wastegate, the

butterfly valve is on a preloaded mechanism to minimise binding at the end

stops, this results in the sensor reading past the home positions and for this

reason the calibration sequence with low

force is essential.

y = -2.1519x3 + 3.0586x2 +

0.0582x + 0.0326 R2 = 0.999

Butterfly Position | Flow Percentage |

0% | 3.3% |

3% | 3.7% |

6% | 4.7% |

10% | 6.7% |

20% | 14.9% |

30% | 26.7% |

40% | 40.8% |

50% | 55.7% |

60% | 70.4% |

70% | 83.4% |

80% | 93.5% |

90% | 99.4% |

100% | 100.0%

|

ADVANCED FEATURES ON THE STRAIGHT WASTEGATE

Water Cooling

- Turbosmart’s StraightGate is equipped with

water cooling ports to keep the wastegate cool in the most extreme conditions

and keep consistent actuator temperature.

- Identify the water cooling ports on the bottom

of the actuator adjacent to the water-cooling symbol engraved in the actuator.

Fit water-cooling port fittings Prior to

mounting the wastegate, install 1/8” NPT fittings into the water ports, apply

thread lubricant and screw in clockwise until finger tight, then tighten

further 1-2 turns for seal. Choose feed and drain source for the water and

connect to the wastegate. Turbosmart recommends -4SAE fittings and hose

compatible with coolant. It is not important which way the water flows

through housing.

CAUTION! Check for leak, ensure the water-cooling

circuit is free from leaks.

How to Conduct Maintenance on Your Electronic StraightGate

Basic Maintenance

The Straight gate will require periodic maintenance depending on application. In high demand, unusually environments, it is advisable to increase the service interval.

Turbosmart recommends that the internal gearbox is regreased with a spray type grease such as Inox MX8 spray grease this should be conducted half yearly or more depending on environment. With the top plate removed grease can be sprayed into the small inspection hole located near the magnet covered by a M4 bolt as well as located near the motor.

Motor Replacement

In the event of the motor failing, it can be

easily replaced. The Motor Housing must be disassembled, the cap must

be removed with the Turbosmart rear housing tool, this opens the rear of the

motor housing, once open the motor wires will need to be moved out of the way.

The black wire is matched to the red dot on the back of the motor cover. With

the wiring clear the 4mm Allen keys will need to be removed. The rear housing

will separate. Pulling it off the back. The replacement motor part number

A 2.5mm Allen key will be required to remove

the motor screws. With both undone. The motor can be lightly pushed out. When reinstalling, use a small application of

Loctite 243.

Sensor Replacement

In the event that the sensor fails, it is located under the top cap, it is held on with two 2.5mm Allen keys for the cap and two 2.5mm for the encoder. The replacement sensor part number (TS-0550-3123). The encoder is located under neath the top cap of the Electronic straight gate. The grommet will remain attached to the top cap and be removed as one piece.

Actuator Replacement

The actuator can be removed and rotated through 3 different orientations; these are parallel to the body, 30 deg to the body and the current configuration 90 deg to the body.

The

actuator locking pins are 3mm Allen keys that lock the body to the actuator. It

is important that the butterfly remains in the same position, the recommended position

is to be just off the valve seat. It is also advisable to not to move the

manual override during this process.

CAUTION! Moving body and actuator while separated will

cause issues with calibration. If moving to one of three mounting options

observe positions before moving readjusting.

CAUTION! Moving body and actuator while separated will

cause issues with calibration. If moving to one of three mounting options

observe positions before moving readjusting.

With

the Allen key pins removed the body can be separated from the actuator and one

of the three options can be picked.

The

actuator locking pins are to be Torqued to 6N/mm as well as a new application

of Loctite 243 is also required.

Troubleshooting

- Wastegate not actuating - Confirm continuity of wiring, manually adjust butterfly position and feel for binding.

- Poor wastegate actuation – Ensure wiring is correct, check for dirt and smooth operation by manual over-ride, ECU that is driving the butterfly may not be set up correctly.

- Wraparound of signal on position sensor – Turbosmart Pre “time” every sensor, contact Turbosmart if this occurs.

- Wastegate fluctuates and fails to find targeted position, motor wires may be the incorrect way. Swap and test to see. Ensure to use sensible current limits to prevent over currenting.

- Wastegate seized – Remove cap and manually move butterfly feeling for resistance.

- Wastegate moves but sensor not reading – Check connections.

- Boost creeping at high rpm - Wastegate flow path is poor, wastegate is too small for the application.

- Failing the above, submit a Technical Support Query Form with information about your engine, oil type and photos of the installation and one our expert technicians will respond as soon as possible.

Important Notes on Your New Electronic StraightGate

Important Notes on Your New Electronic StraightGate

Recommendations

Recommendations

Kit Contents

Kit Contents

Tools Required

Tools Required

Suggested lubricants and Sealants

Suggested lubricants and Sealants

CAUTION! Do not place the Straight Gate

near a significant heat source as this could shorten the life of the internal

electronics.

CAUTION! Do not place the Straight Gate

near a significant heat source as this could shorten the life of the internal

electronics.

NOTE! Turbosmart

recommends allowing additional clearance from the end stops until the wastegate

control is tuned to minimise risk of overshoot into end stops at high speeds.

NOTE! Turbosmart

recommends allowing additional clearance from the end stops until the wastegate

control is tuned to minimise risk of overshoot into end stops at high speeds.

CAUTION! Moving body and actuator while separated will

cause issues with calibration. If moving to one of three mounting options

observe positions before moving readjusting.

CAUTION! Moving body and actuator while separated will

cause issues with calibration. If moving to one of three mounting options

observe positions before moving readjusting. Troubleshooting

Troubleshooting