Compressed Gas / CO2 External Straight Gate Instructions

Product Name: | Compressed Gas Wastegate |

Product Description: | PSG 40/50/76 Pneumatic Straight Gate Compressed Gas 7 Psi |

Product Number: | TS-0565-1242 TS-0565-1252 TS-0563-1242 TS-0563-1252 TS-0567-1242 TS-0567-1252 |

Important Notes on Your New Compressed Gas Straightgate

Important Notes on Your New Compressed Gas Straightgate

- Turbosmart

accepts no responsibility whatsoever

for incorrect installation of this product which is potentially

hazardous and can cause serious engine damage or personal

injury

- The compressed gas straight gate is designed for use with a turbocharger

that does not have an internal wastegate.

- Consult your local specialist before setting

your desired boost pressure,

setting boost beyond your

engines capability may result in engine damage.

- Use only high-quality fittings ensuring maximum sealing reliability. Optional Turbosmart fitting kit available.

Recommendations

Recommendations

- Allow for

adequate cool airflow around the top diaphragm housing

- DO NOT Mount the wastegate so that the top diaphragm housing is less

than 100mm from a heat source

- DO NOT wrap the body of the wastegate with

exhaust wrap

- Fitting

your compressed gas straightgate may require fabrication or modification to your exhaust

manifold. Turbosmart recommends that your wastegate

is fitted by an appropriately qualified technician.

- Turbosmart

recommends that the engines Air/Fuel ratio is checked while setting the desired

boost pressure, as any increase in boost pressure can cause the engine to run “LEAN”, resulting in possible

engine damage.

- Turbosmart

recommends that boost pressure is set using

a dynamometer and not on public roads.

- Turbosmart recommends that a boost gauge be permanently fitted to the vehicle.

Kit Contents

Kit Contents

Part | Description | Use |

1 | Turbosmart Compressed Gas Straight Gate | Main Unit |

2 | Inlet Weld Flange | Inlet Weld Flange |

3 | Outlet Weld Flange | Outlet Weld Flange |

4 | Inlet V-Band Clamp | Inlet V-Band Clamp |

5 | Outlet V-Band Clamp | Outlet V-Band Clamp |

6 | Fitting Kit | 2 x 1/8" NPT Nipple, 1/8" NPT Blanking Plugs ** (1x pre-installed) |

7 | Spring Kit | 4 x Springs ** (1x Spring pre installled)** |

8 | Collar Tool | Collar Tool |

9 | Turbosmart Sticker | Turbosmart Sticker |

Tools Required

Tools Required

- 3/8" square drive deep socket

- Square drive ratchet wrench

- Torque wrench (3/8" drive)

- Non-marking spanners to tighten fittings

- 3/16" hex key

- Supplied collar tool

- 14mm 12-point (double hex) socket

- Flat blade screwdriver

SUGGESTED

LUBRICANTS AND SEALANTS

SUGGESTED

LUBRICANTS AND SEALANTS

SUGGESTED

LUBRICANTS AND SEALANTS

SUGGESTED

LUBRICANTS AND SEALANTS - Loctite 243 Thread locker

- Loctite 567 Thread Sealant

- Resbond 907TS Red

- Penetrating oil

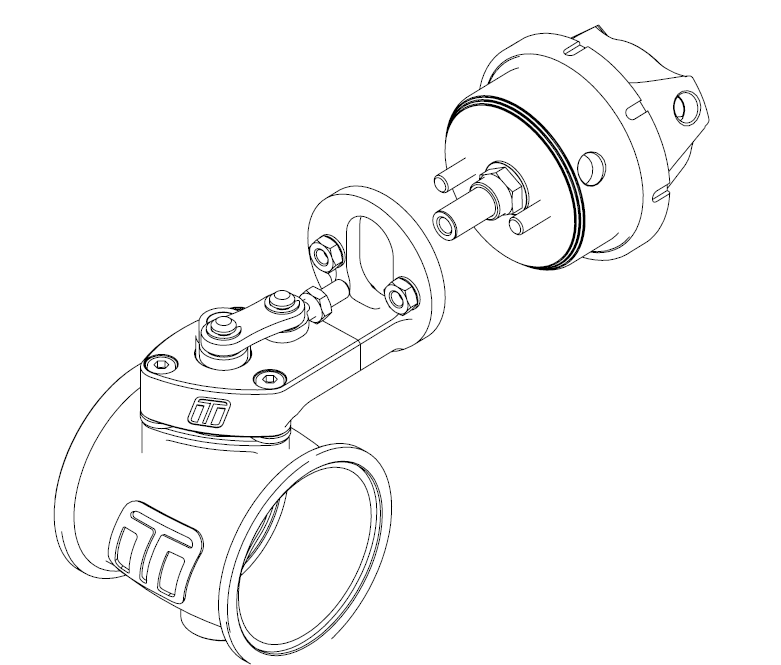

Compressed Gas Wastegate Overview (Pictured without Solenoids)

Fitting Your CO2 Straight Gate

Mounting your new Turbosmart Wastegate

The GenV series of wastegate is a direct fit replacement for the 4th Gen wastegate range and no modification is necessary provided packaging space is sufficient. The weld flanges should be welded to your exhaust system. The weld flanges are compatible with Stainless Steel and Mild steel welding rod material. For best results an attempt should be made, if space allows, to mount the GenV Wastegate at an angle to the exhaust flow to allow for better flow than a 90 degree mounting. See the schematic diagrams below for examples of mounting positions.

(Best Flow) Symmetric mounting allows an excellent flow of

exhaust to the Straight Gate

Fitting the Compressed Gas Straight gate

Prior to mounting the Straight Gate, place v-band over weld on flange by unscrewing the nut on the v-band as far out as possible and then squeezing the bolt in a syringe motion to expand the v-band (squeeze the dots together below). Once the v-band is in its fully expanded position, slide the v-band over the flange to allow for the wastegate to be installed.

Fit Actuator Port Fittings

Clocking Actuator

Compressed Gas Wastegate Hook-Up

Compressed Gas Setup

- Port 1 (Regulated CO2 Supply)

- Port 2 (CO2 "Top Cap")

- Port 3 (Blocked)

- Port 1 (CO2 "Top Cap")

- Port 2 (Vent to Atmosphere)

- Port 3 (Blocked)

Integrated Solenoid Gas Setup

- Port A (Regulated CO2 Supply)

- Solenoid A

- Port B (Vent to Atmosphere)

- Solenoid B

Wiring Hookup

Start Engine and check for leaks.

Congratulations,

your CO2 Straight Gate is installed and ready for use. Double check all fittings,

lines and mountings then proceed to start engine and check for leaks.

HOW TO CHANGE YOUR COMPRESSED GAS SPRING

Remove Compressed Gas Straight Gate from Manifold

Remove Top Cap

Familiarise

Yourself with Cap and Body Notches

Locate cap and body notches and grooves which dictate the alignment of the cap. These notches are used to locate the cap onto the body and must be aligned prior to compression of the cap onto the body.

Press Cap

onto Body

Using a press or vice, comp the notches are remaining aligned. Once the cap has seated home onto the body, screw the collar down by hand in a clockwise direction. While still in the press or vice, Tighten the collar further with the collar tool until the collar will not turn.

Reinstall

Compressed Gas Straight Gate

Achieving Your Target Boost Pressure

There are various factors involved in achieving your target boost pressure including.

- The size of

the spring fitted in your wastegate i.e. the boost pressure achieved by the

wastegate spring only.

- The desired level of boost pressure and the difference between this and your wastegate spring pressure.

- The size of

your turbocharger and wastegate and the resulting exhaust manifold back pressure in your system.

- The amount of dome pressure that is fed into the top cap.

IMPORTANT

NOTES ON SETTING THE WASTEGATE SPRING

PRESSURE

IMPORTANT

NOTES ON SETTING THE WASTEGATE SPRING

PRESSURE Location | Inner | Inner | Middle | Outer |

Pressure | 6psi | 9psi | 12psi | 21psi |

Colour | Black | Grey | Pink | Red |

6psi | ● |

|

|

|

9psi |

| ● |

|

|

12psi |

|

| ● |

|

18psi | ● |

| ● |

|

21psi |

| ● |

How to Change Your Straight Gate Wastegate Diaphragm

Remove Actuator from Body

Remove

fittings from the wastegate as well as the

breather hose if fitted. Unscrew outlet V-Band nut in a anti-clockwise

direction to the very end of the thread, Squeeze the nut

against the V-Band in a syringe like motion to expand the V-band over

the flange. Repeat for inlet V-Band. Remove straight gate. Mark the orientation

of the valve to the body with tape or a paint pen.

Diaphragm Replacement

The actuator must be removed for ease of disassembly of the diaphragm replacement. The once removed the top cap can come off and the diaphragm can be swapped out.

Align the

valve orientation marks and confirm the diaphragm bead is

seated in the groove of the actuator. Install desired spring combination. Configure

Wastegate with preferred spring combination of inner,

middle and outer springs

Familiarise

Yourself with Cap and Body Notches

Locate cap

and body notches and grooves which dictate the alignment

of the cap. These notches are

used to locate the cap onto the

body and must be aligned prior to compression of the cap onto

the body.

Press cap

onto body

Using a

press or vice, compress the cap onto the body ensuring the notches

are remaining aligned. Once the cap has seated home onto

the bod, screw the collar down by hand in a clockwise direction.

While still in the press or vice, Tighten the collar further with the

collar tool until the collar will not turn.

Reinstall fittings to the cap of the wastegate using fresh sealant.

Reinstall straight gate

HOW TO INSTALL A SENSOR CAP TO YOUR COMPRESSED GAS STRAIGHTGATE

The Compressed Gas Straight Gate comes with a pre-installed magnet on the diaphragm, essential for HE sensor operation. To install the sensor (sold separately), simply remove the top blanking plate and fit the HE sensor in its place. Calibration may be required depending on your system.

Connect the wires to your data logger accordingly. Use a high-quality connection to reduce noise and calibration fluctuation.

To ensure longevity from the sensor, ensure adequate airflow is supplied directly to the sensor to avoid overheating or sensor failure.

Turbosmart HE sensor has an operation temperature window of -40C up to 170ºC (340ºF) junction temperature, for temperatures outside of this window the VOUT will revert to less than 2.5V

Temperature

exposure above 260ºC (500ºF) can cause permanent damage to the sensor.

Calibration*

Insert the

relevant calibration curve into your data logger for the Compressed Gas Straight Gate

Rod Travel (mm) | Voltage Out |

0 | 0.44 |

2 | 1.21 |

4 | 1.58 |

6 | 1.84 |

8 | 2.00 |

10 | 2.13 |

12 | 2.21 |

14 | 2.27 |

16 | 2.32 |

18 | 2.36 |

*NOTE! For best

results, each wastegate should be calibrated to your

setup.

*NOTE! For best

results, each wastegate should be calibrated to your

setup.  Troubleshooting

Troubleshooting

- Wastegate

not actuating - Confirm signal hose is plumbed to a pressure only source,

confirm preload on valve seat during installation

- Poor

wastegate actuation - Ensure signal hose is not shared and is sourced as close

to the compressor as possible, check seal on fittings

- Poor

wastegate actuation - Confirm Top ports are not blocked and free from debris

- Boost

creeping at high rpm - Wastegate flow path is poor, wastegate is too small for

the application

- Failing the above, submit a Technical Request Form with information about your engine, oil type and photos of the installation and one our expert technicians will respond as soon as possible.

Related Articles

Compressed Gas / CO2 External Wastegate Instructions

Product Name: Compressed Gas Wastegate Product Description: GenV Compressed Gas Wastegate Product Number: TS-0552-1242 TS-0553-1242 TS-0554-1242 TS-0555-1242 Important Notes on Your New Compressed Gas External Wastegate Turbosmart accepts no ...Pneumatic Boost Gate Compressed Gas

Product Name: Pneumatic Boost Gate Compressed Gas Product Description: PBG 50/76 Pneumatic Boost Gate Compressed Gas 7 Psi /Solenoid Product Number: TS-0265-1242 TS-0265-1252 TS-0267-1242 TS-0267-1252 Important Notes on Your New Compressed Gas Boost ...TS-0265-1042 - eBG50 Electronic Boost Gate

Product Name: eBG50 Electronic BoostGate50 Black Product Description: eBG50 Electronic BoostGate50 Black Product Number: TS-0265-1042 Important notes on your new Electronic Boost Gate The electronic boost gate is designed for use with a forced ...TS-0565-1212-PSG50V Vacuum Pneumatic Straight Gate-Instructions

Product Name: PSG50V Vacuum Pneumatic Straight Gate Product Description: PSG50V Vacuum Pneumatic Straight Gate Product Number: TS-0565-1212 Important Notes on Your External Wastegate Turbosmart accepts no responsibility whatsoever for incorrect ...Gas Valve Actuator

Product Name: Gas Valve Actuator Product Description: GVA 40/45/50/60mm Product Number: TS-0552-1712 TS-0553-1712 TS-0554-1712 TS-0555-1712 Important notes on your new Gas Valve Actuator (GVA) Turbosmart accepts no responsibility whatsoever for ...